1. Introduction

As the automotive industry undergoes a major transformation toward electrification, intelligence, and connectivity, automotive-grade chips have become the “digital heart” of vehicles, playing a critical role in shaping vehicle performance and functionality, and are becoming increasingly important.

Although all are chips, automotive-grade chips differ significantly from the commonly known consumer-grade chips due to their different application scenarios. This article will explore the concept of automotive-grade chips in depth and compare them with regular chips to analyze their differences.

2. Definition of Automotive-Grade Chips

Automotive-grade chips refer to semiconductor chips that meet automotive industry standards and are used in automotive electronic systems. They can be broadly categorized into three types:

The first type is computing chips, which are responsible for processing large volumes of data. For example, autonomous driving chips need to analyze and make decisions based on massive amounts of data collected by cameras, radars, and other sensors in real time. The second type is power chips, which handle power transmission and conversion in vehicles. For instance, the inverter chip in electric vehicles determines the efficiency of power conversion from battery to motor. The third type is sensor chips, which detect various physical states of the vehicle. For example, tire pressure sensor chips can monitor tire pressure in real time to ensure driving safety.

3. Importance of Automotive-Grade Chips

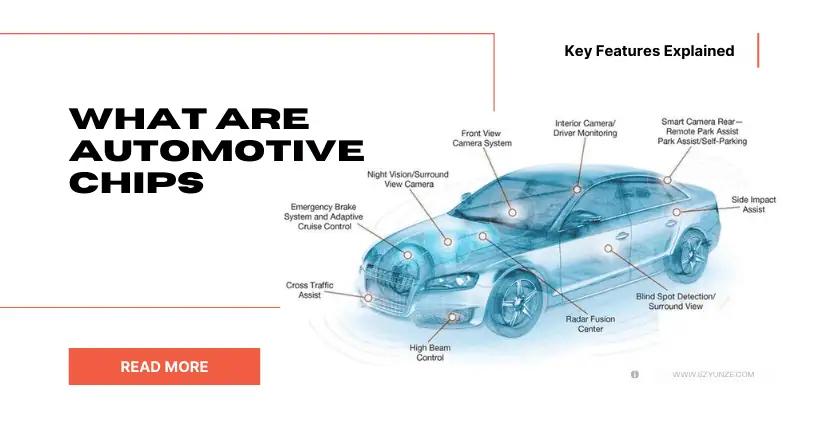

Automotive-grade chips play an irreplaceable and crucial role in the automotive industry. In traditional fuel vehicles, chips are mainly used in engine control units, anti-lock braking systems, and so on, to optimize vehicle performance and improve driving safety. In the era of new energy vehicles, the role of chips has become even more prominent. For example, autonomous driving systems heavily rely on high-performance automotive-grade chips to analyze road conditions in real time and enable assisted driving functions.

In addition, automotive-grade chips are also the core of vehicle connectivity. With the help of chips, vehicles can interact with the external environment, providing users with intelligent services such as remote control and real-time navigation.

4. Features of Automotive Chips

Compared to regular consumer-grade chips, automotive-grade chips operate in harsher environments and require higher stability and reliability. The key differences include:

✅ Operating Temperature and Environmental Adaptability

Consumer-grade chips are usually designed for indoor use, with an operating temperature range generally between 0℃ and 70℃. However, vehicles operate in complex environments, and automotive-grade chips must function reliably in extreme temperatures ranging from -40℃ to 150℃.

For instance, in cold northern winters, chips must quickly become operational when the vehicle starts; in hot summers, engine compartments reach high temperatures, yet chips must still function properly. Moreover, automotive-grade chips must endure intense vibrations, shocks, moisture, dust, and other harsh conditions, while consumer-grade chips have much lower tolerance for such environmental factors.

✅ Reliability, Safety, and Fault Tolerance Mechanisms

Vehicle safety concerns human lives, so automotive-grade chips must meet extremely high safety standards. For example, the functional safety standard ISO 26262 imposes strict requirements on the design and production of automotive-grade chips, which must incorporate multiple redundancy designs and fault detection mechanisms.

If a part of the chip fails, the system must swiftly switch to backup modules to ensure critical vehicle functions remain unaffected. Consumer-grade chips, while considering a certain level of safety, are far less stringent in this regard.

5. Differences in Design and Manufacturing Approaches

✅ Design Philosophy

Consumer chips focus on high performance and low power consumption to meet the demands of devices like smartphones and computers for speed and battery life. For example, smartphone chips continuously improve computing speed and graphics capabilities to support HD games and complex multimedia applications.

In contrast, automotive-grade chip design prioritizes stability and reliability. Computing speed is not the top priority. In designing autonomous driving chips, ensuring accuracy and real-time data processing to avoid decision errors is more important than simply pursuing high-speed computation.

✅ Manufacturing Process and Testing Procedures

To achieve higher performance and integration, consumer-grade chips often adopt advanced manufacturing processes, such as 5nm or even 3nm technology. These advanced processes integrate more transistors in a smaller chip area, enhancing performance. Automotive-grade chips, which emphasize stability, have relatively flexible requirements for process nodes and commonly use 16nm to 28nm processes.

Additionally, the testing procedures for automotive-grade chips are extremely rigorous. In addition to standard functional testing, they must undergo multiple reliability tests, such as high-temperature aging and thermal cycling tests, to ensure chip quality. In comparison, consumer chip testing processes are relatively simpler.

6. Conclusion and Outlook

In summary, due to differences in application scenarios, automotive-grade chips and consumer-grade chips show significant distinctions in performance, design, and manufacturing. Consumer chips are more sensitive to performance, power consumption, and process technologies, often using the most advanced manufacturing processes. Automotive-grade chips are more sensitive to stability, reliability, and cost, and are less dependent on cutting-edge manufacturing, usually choosing the most cost-effective and mature process nodes.

Although automotive and consumer chips will continue to evolve along their own paths, there is potential for mutual inspiration in technology. For example, the advanced manufacturing techniques of consumer chips might offer new directions for automotive chips, while the high-reliability design of automotive chips could inspire improvements in consumer chips, driving the entire semiconductor industry to new heights.

Related:

- Explore Logic Chips: Types and Key Differences with Analog

- Nintendo Switch 2 Teardown Reveals Key Suppliers by iFixit

- Unlock the Success Formula for Chips in the AI Era Today

- Chip Packaging 101: A Beginner’s Comprehensive Guide

Disclaimer:

- This channel does not make any representations or warranties regarding the availability, accuracy, timeliness, effectiveness, or completeness of any information posted. It hereby disclaims any liability or consequences arising from the use of the information.

- This channel is non-commercial and non-profit. The re-posted content does not signify endorsement of its views or responsibility for its authenticity. It does not intend to constitute any other guidance. This channel is not liable for any inaccuracies or errors in the re-posted or published information, directly or indirectly.

- Some data, materials, text, images, etc., used in this channel are sourced from the internet, and all reposts are duly credited to their sources. If you discover any work that infringes on your intellectual property rights or personal legal interests, please contact us, and we will promptly modify or remove it.