In the solder paste process, cold solder joints are a common soldering defect, characterized by a solder joint that appears to be connected but actually has poor electrical contact or insufficient mechanical strength. Cold solder joints may lead to product failure, decreased reliability, and even the risk of a short circuit. Below is a detailed analysis of the causes, manifestations, impacts, detection, and preventive measures:

01

Definition and Hazard of Cold Solder Joints

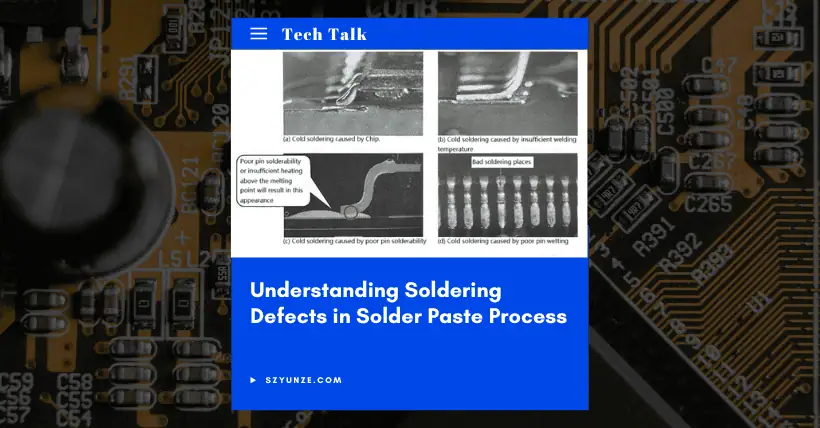

Cold solder joints refer to a phenomenon where there is no effective electrical connection between component pins and PCB pads, with open soldering being the most common defect type. As shown in Figure 1-1, typical cold solder joints include cases where the pin is lifted, leading to missing solder spots, or where the solder paste fails to wet properly, forming cold joints. This defect is highly concealed and may cause intermittent faults in equipment, making it a high-risk process issue. Some manufacturers use toothpick probing as an initial screening method, but excessive reliance on manual operations may lead to quality fluctuations.

02

Causes of Cold Solder Joints

Based on the process chain stages, the causes of cold solder joints can be divided into five categories, exhibiting strong randomness and process sensitivity:

✅ Solder Paste Printing Defects

Manifestation: Insufficient solder paste due to missed or under-printed areas (e.g., small solder spot areas in Figure 1-1); steel mesh clogging or improper parameter design (e.g., too small apertures).

Cold solder joint proportion: About 35% (industry statistics, actual proportion may vary depending on process conditions).

✅ Pin Coplanarity Issues

Manifestation: Pin lifting or deformation causes partial pins to be detached from the solder paste contact (e.g., pin lifting areas in Figure 1-1).

Cold solder joint proportion: About 28%.

✅ Via Siphon Effect

Manifestation: Improper design of PCB pad vias leads to molten solder flowing into the via, causing insufficient solder at the pin base (e.g., via pad areas in Figure 1-1).

Cold solder joint proportion: About 18%.

✅ Solderability Decline

Manifestation: Pin electroplating layer oxidation (e.g., insufficient Sn layer thickness) or PCB pad surface contamination.

Cold solder joint proportion: About 15%.

✅ Thermodynamic Imbalance

Manifestation: PCB’s large thermal capacity or insufficient preheating causes solder paste to climb up along the pin after melting (capillary effect).

Cold solder joint proportion: About 4%.

03

Systematic Improvement Suggestions

A “design-material-process” integrated control system should be established:

✅ Strengthening Material Control

Pin Protection: Use vacuum packaging for transportation, and complete mounting within 48 hours after unpacking. Storage humidity should be ≤10% RH.

Solderability Verification:

Pin electroplating layer thickness ≥8 μm (Sn layer), use a wetting balance tester (WBT) to ensure a contact angle ≤90°.

PCB pads should undergo plasma cleaning, with periodic surface energy testing ensuring ≥50 mN/m.

✅ Process Parameter Optimization

Printing Process:

Use a step steel mesh (thickness 0.12-0.15mm), with aperture area 10-15% larger than the pin size.

Implement solder paste thickness monitoring (SPI), with target thickness of 60-80 μm.

Soldering Profile:

Preheating zone temperature should be raised to 120-140°C, with a time extension to 120-150 seconds.

Peak temperature should be 245±5°C, with liquidus time >40 seconds.

Equipment Maintenance:

Clean the steel mesh every 20 PCBs using a dedicated solvent and lint-free cloth.

Calibrate the reflow soldering temperature weekly, ensuring ΔT ≤5°C.

✅ Detection System Upgrade

AOI + X-ray Integration:

AOI should focus on detecting solder wetting angles (qualified standard: <30°) and pin coplanarity.

X-ray should inspect the void percentage of solder joints (IPC standard: <25%).

SPC Process Control:

Real-time control charts should be used to monitor key parameters such as soldering temperature and printing thickness.

Establish a cold solder joint defect database and implement PDCA continuous improvement.

✅ Operational Specification Optimization

Programming before soldering is prohibited: Prevent deformation of pins due to force, and use non-contact tooling for programming operations.

Material flow control: Use anti-static turnover carts to avoid pin collisions and deformation.

✅ Expected Implementation Results

With the above improvement plan, it is expected that:

The cold solder joint rate will be reduced to below 0.5% (industry excellence level).

Soldering quality stability will improve by 40%.

Rework costs will be reduced by more than 60%.

Product reliability (MTBF) will increase by 30%.

It is recommended to prioritize the optimization of the solder paste printing process and AOI detection upgrade, which can be completed within 3 months and show significant improvements. In the long term, a DFM design rule library should be established to eliminate the risk of cold solder joints from the source.

Summary: Cold solder joints are a key control point in the solder paste process, requiring system management from materials, equipment, process, and environment. Through strict process control and real-time monitoring, the cold solder joint rate can be significantly reduced, improving product reliability.

Related:

- Should You Place Vias Directly on Pads? Find Out Now

- Key Steps to Mastering the Lead Free Soldering Process

- Next-Gen Samsung HBM May Adopt Fluxless Technology

- Solder Paste Creation: Nano Powders to Final Form

Disclaimer:

- This channel does not make any representations or warranties regarding the availability, accuracy, timeliness, effectiveness, or completeness of any information posted. It hereby disclaims any liability or consequences arising from the use of the information.

- This channel is non-commercial and non-profit. The re-posted content does not signify endorsement of its views or responsibility for its authenticity. It does not intend to constitute any other guidance. This channel is not liable for any inaccuracies or errors in the re-posted or published information, directly or indirectly.

- Some data, materials, text, images, etc., used in this channel are sourced from the internet, and all reposts are duly credited to their sources. If you discover any work that infringes on your intellectual property rights or personal legal interests, please contact us, and we will promptly modify or remove it.