The bonding of die chips is a process method used to mount chips on a packaging substrate. This article provides a detailed introduction to several main methods and processes for chip bonding.

1. What is Chip Bonding

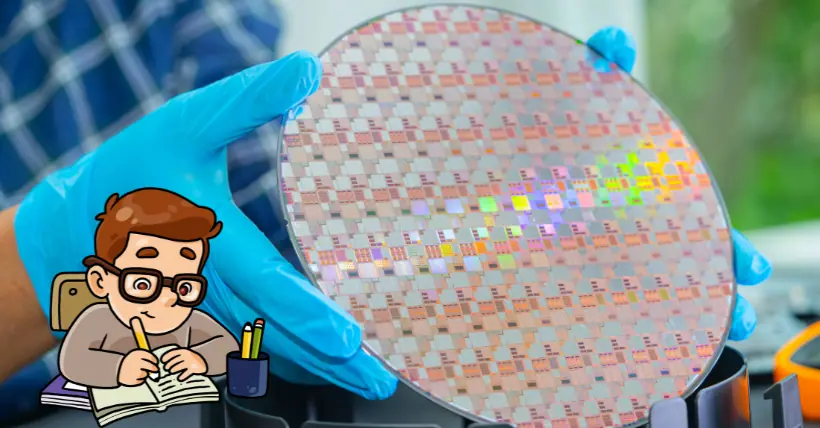

In semiconductor processes, “bonding” refers to the connection of a wafer chip to a substrate. The connection can be divided into two types: traditional methods and advanced methods. Traditional methods include wafer bonding and wire bonding, while advanced methods include flip-chip bonding, developed by IBM in the late 1960s. Flip-chip bonding is a method that combines die bonding and wire bonding, connecting the chip and substrate by forming bumps on the chip pads.

Just like an engine is installed in a car to provide power, semiconductor chips are connected to a lead frame or printed circuit board (PCB) to link the chip circuits to the outside. After the chip is connected, it should withstand the physical pressure generated after packaging and dissipate the heat produced during the chip’s operation. If necessary, it must maintain constant conductivity or achieve a high level of insulation. Therefore, as chips become smaller, bonding methods become increasingly important.

2. Die Bonding Process

In traditional chip bonding methods, the first step is to apply adhesive on the packaging substrate, then place a chip on it, with the side with pins facing up.

In the flip-chip bonding process, which is part of advanced packaging, the chip is placed with the side with pins facing down, and the small solder ball protrusions on the pins attach to the pads on the chip.

In both methods, the assembled unit passes through a tunnel called temperature reflow, which adjusts the temperature over time to melt the adhesive or solder balls. It is then cooled to fix the chip (or bumps) on the substrate.

3. Chip Pick and Place Process

The process of individually picking chips attached to tape is called “Pick.” When the nozzle picks up the chips from the wafer and places them on the surface of the packaging substrate, it is called “Place.” These two actions are collectively known as the “Pick & Place” process. This process can also involve sorting good chips by inputting wafer test results (Go/No Go).

4. Chip Ejection

Every chip that has undergone the dicing process is weakly adhered to tape. At this time, it is not easy to pick up chips that are placed horizontally on the dicing tape one by one. This is because even using a vacuum suction nozzle, it is not easy to pull them up, and if forcibly pulled out, it may cause physical damage to the chip.

Therefore, “Ejection” becomes an easier method for picking chips. The ejector applies physical force to the target chip, creating a slight step difference from other chips. The chip is ejected from the bottom and pulled up with a vacuum nozzle from above. At the same time, the vacuum pulls the tape from the bottom to flatten the wafer.

5. Chip Bonding Process

When using epoxy resin for die bonding, a very small amount of epoxy is precisely applied to the substrate through dispensing. After placing the chip on it, the epoxy is hardened through reflow or curing at 150 to 250°C to bond the chip and substrate together.

If the thickness of the applied epoxy is not uniform, warping or deformation may occur due to differences in thermal expansion coefficients. For this reason, controlling the amount of glue is very important. However, as long as epoxy is used, any form of warping can occur.

This is why more advanced bonding methods using die attach film (DAF) are becoming the preferred choice. Although DAF has some disadvantages such as being expensive and difficult to handle, its thickness can be well controlled, and it simplifies the process, leading to its increasing usage.

6. Die Attach Film (DAF) Bonding

DAF (Die Attach Film) is a thin film attached to the bottom of the die. Using DAF, the thickness can be adjusted to be thinner and more consistent than when using polymer materials. It is widely used not only for bonding chips to substrates but also for bonding chips to chips to create multi-chip packages (MCP).

From the structure of the diced chip, the DAF located at the bottom of the chip supports the chip, while the dicing tape pulls the DAF underneath, with weaker adhesion. To perform die bonding in this structure, the die should be placed on the substrate after picking up the chip and DAF from the dicing tape, without using epoxy resin. This process skips the dispensing step, making it faster and perfectly avoiding problems caused by uneven dispensing thickness.

When using DAF, some air can penetrate the film, causing deformation and other issues. Especially, the equipment handling DAF requires high precision. However, DAF is preferred because it can reduce defect rates, improve productivity, simplify the process, and increase thickness uniformity.

The method of die bonding varies greatly depending on the type of substrate (lead frame or PCB). For a long time, PCB-based substrates have been frequently used because they allow for mass production of small-sized packages. As bonding technology diversifies, the temperature distribution of baked adhesives is also continuously evolving. Representative bonding methods include thermocompression or ultrasonic bonding. As packaging continues to move toward ultra-thin types and integration levels increase, packaging technology is also diversifying.

Related:

- How Many Layers Are in UV Tape Used for Wafer Dicing?

- Discover SIP Technology and Its Role in 16GB DDR4 Chips

- How Die Attach Ensures Chip Stability and Performance?

- Metal ECP: How Much Edge Cleaning is Needed?

- Next-Gen Samsung HBM May Adopt Fluxless Technology

- 2nm Process Nodes Reveal Critical Chip Yield Issues

Disclaimer:

- This channel does not make any representations or warranties regarding the availability, accuracy, timeliness, effectiveness, or completeness of any information posted. It hereby disclaims any liability or consequences arising from the use of the information.

- This channel is non-commercial and non-profit. The re-posted content does not signify endorsement of its views or responsibility for its authenticity. It does not intend to constitute any other guidance. This channel is not liable for any inaccuracies or errors in the re-posted or published information, directly or indirectly.

- Some data, materials, text, images, etc., used in this channel are sourced from the internet, and all reposts are duly credited to their sources. If you discover any work that infringes on your intellectual property rights or personal legal interests, please contact us, and we will promptly modify or remove it.