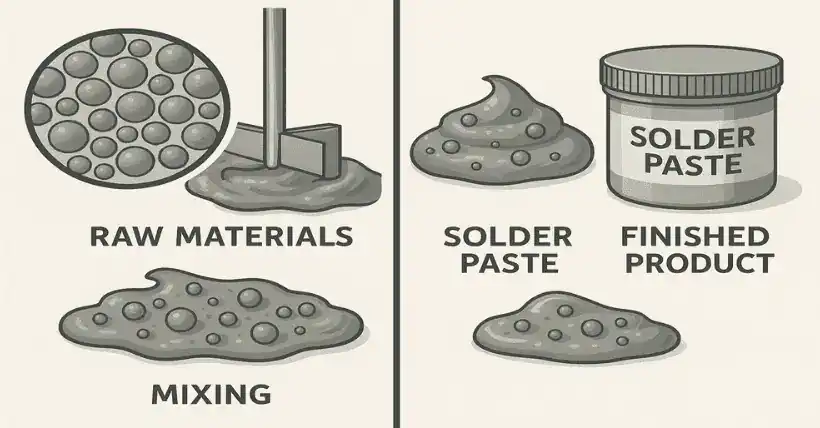

The preparation of solder paste represents a deep integration of materials science and precision engineering, centered on the accurate ratio of metal alloy powder and flux, achieving microscopic structural uniformity and stable macroscopic performance through multiple processes. In this article, engineers from YUNZE TECHNOLOGY LIMITED, from the perspective of a solder paste manufacturer, guide you through the entire process from raw material selection to finished product inspection, revealing the “molecular-level” secrets of solder paste manufacturing.

01

Rigorous Raw Material Selection of Solder Paste Creation: Starting with Micron-Level Precision

The core components of solder paste consist of metal alloy powder (85–92%) and flux (8–15%), whose purity and particle size directly affect soldering performance:

The metal alloy powder uses tin-based alloys with ≥99.9% purity (e.g., SnAgCu, SnBi, SnZn), processed into spherical particles via gas atomization or centrifugal atomization. Depending on the application, particle sizes range from T1 (75–150μm) to T10 (1–3μm). For example, T6 (5–15μm) powder is used in soldering battery modules of new energy vehicles to ensure printing accuracy and vibration resistance.

Flux is a compound of resin (carrier), organic acid (activator), diol ether (solvent), and thixotropic agent. For instance, lead-free solder paste commonly uses rosin-based resin, with adipic acid as the activator. Solvent surface tension is controlled at 25–35mN/m, with an acid value of 5–20mg KOH/g to ensure effective activation within 120–260℃.

Purity and stability of raw materials are strictly controlled. Metal powder must pass ICP-MS impurity testing (lead, cadmium <5ppm), and flux must meet viscosity (50–150Pa·s) and surface insulation resistance (>10^13Ω) standards to ensure component stability.

02

Process Innovation: Four Steps to Achieve “Molecular-Level” Uniformity

✅ Pre-Mixing of Raw Materials

Metal powder and flux are proportioned (e.g., 89:11) and placed into a dual planetary mixer, stirred at low speed (50–100rpm) under vacuum for 5–10 minutes to initiate powder wetting. Environmental temperature and humidity (20–25℃, humidity ≤40%) must be controlled to prevent flux moisture absorption and metal oxidation.

✅ Grinding and Dispersion

The pre-mixture enters a three-roll mill, where rollers with 0.05–0.1mm gaps repeatedly compress the material to fully integrate metal particles and flux. Precision solder paste requires 3–5 passes of grinding until particle distribution is uniform (D50 within ±10% of target size) while avoiding high temperatures that cause solvent evaporation.

✅ Homogenization Mixing Stage

The ground paste is transferred to a vacuum mixer, stirred at 200–300rpm for 15–20 minutes. Shear forces disperse metal particles uniformly, stabilizing viscosity at 50–150Pa·s. Real-time viscosity monitoring (using a rotational viscometer) ensures inter-batch consistency error <5%.

✅ Finished Product Inspection

The physical and chemical properties of the solder paste are tested using precise instruments simulating application conditions to verify reliability and stability. Key tests include:

- Particle Size Analysis: Laser particle size analyzers remove coarse (>150% target size) and fine (<20% target size) particles to prevent printing issues such as clogging or collapse.

- Activity Test: Heated at 180℃ for 10 minutes to observe flux’s ability to remove copper foil oxide; requires mirror-like copper surface brightness >90%.

- Reflow Verification: Simulated soldering curve (e.g., 245℃ peak for lead-free paste) checks solder joint void rate (<5%) and wetting area (≥95% of pad) to ensure reliability.

Once tested and approved, the solder paste is nitrogen-filled (O₂ <100ppm) and packaged into 500g cans, 1kg barrels, or syringes, with labels indicating composition, batch number, and shelf life (typically 6–12 months), and stored at 0–10℃ in refrigeration.

03

Key Control Points: Guaranteeing Industrial-Grade Precision

Solder paste preparation requires stringent environmental and equipment standards. The entire process takes place in a Class 10,000 cleanroom (≤352,000 particles/m³) to avoid contamination. Equipment is precisely calibrated, including weekly calibration of roller gaps (±0.001mm) and mixer speeds (±2%) to ensure process repeatability. Each batch retains a 50g sample, recording raw material batch numbers, process parameters, and test data for full traceability.

From the atomization of high-purity metals to nano-level flux compounding, from micron-level grinding with three-roll mills to rigorous full-process testing, every step of solder paste preparation embodies the industrial philosophy that “quality lies in the details.”

Related:

Disclaimer:

- This channel does not make any representations or warranties regarding the availability, accuracy, timeliness, effectiveness, or completeness of any information posted. It hereby disclaims any liability or consequences arising from the use of the information.

- This channel is non-commercial and non-profit. The re-posted content does not signify endorsement of its views or responsibility for its authenticity. It does not intend to constitute any other guidance. This channel is not liable for any inaccuracies or errors in the re-posted or published information, directly or indirectly.

- Some data, materials, text, images, etc., used in this channel are sourced from the internet, and all reposts are duly credited to their sources. If you discover any work that infringes on your intellectual property rights or personal legal interests, please contact us, and we will promptly modify or remove it.