Researchers at the Massachusetts Institute of Technology (MIT) have developed a new technique for manufacturing materials that makes them flexible while maintaining strength and some stiffness.

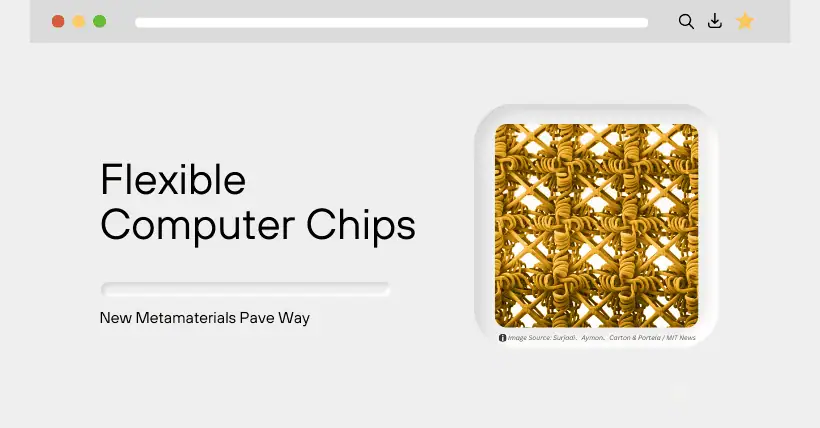

According to MIT News, the research team achieved this by using a micro-dual-network design that combines microscopic pillars with a woven architecture. This combination was first tested on a polymer similar to plexiglass, which allowed it to stretch up to four times its size before breaking. However, the same technique can be applied to other materials, such as glass, ceramics, and metals, expanding its potential applications to industries like semiconductors.

This supermaterial design gains strength from the microscopic pillars and trusses, making it hard but brittle. However, by adding linear support structures made of coils that wrap around the framework, the polymer material is able to stretch three times its size before failure, ten times more than materials that use only basic lattice structures.

“We are opening up this new area for metamaterials,” said Carlos Portela, an associate professor at MIT and a member of the team behind the research. “You can print dual-network metals or ceramics, and you can get a lot of these benefits because it takes more energy to break them, and they have much better stretchability.”

The secret to its increased flexibility lies in the knotting and entangling of the helical structures within the lattice framework. This allows it to absorb more stress, and when cracks form in the pillars, the energy is distributed unevenly throughout the material, making it less likely for cracks to propagate.

“Think of this woven network as a bundle of pasta tangled in the lattice. When we break the overall lattice network, those damaged parts come along, and now all the pasta is entangled with the lattice sheets,” Portela told MIT News. “This promotes more entanglement between the woven fibers, meaning you have more friction and more energy dissipation.”

This new technology could be applied to semiconductors, enabling manufacturers to build flexible chips that can be installed in clothing and other wearable accessories. In addition, the research team is exploring the use of two different materials within the structure. One example is using polymers that respond differently to temperature, so the material becomes softer and more compliant in cold environments, while becoming harder and more rigid at high temperatures.

Related:

Disclaimer:

- This channel does not make any representations or warranties regarding the availability, accuracy, timeliness, effectiveness, or completeness of any information posted. It hereby disclaims any liability or consequences arising from the use of the information.

- This channel is non-commercial and non-profit. The re-posted content does not signify endorsement of its views or responsibility for its authenticity. It does not intend to constitute any other guidance. This channel is not liable for any inaccuracies or errors in the re-posted or published information, directly or indirectly.

- Some data, materials, text, images, etc., used in this channel are sourced from the internet, and all reposts are duly credited to their sources. If you discover any work that infringes on your intellectual property rights or personal legal interests, please contact us, and we will promptly modify or remove it.