I. Introduction to Common Thin Film Growth Technologies

✅ CVD Thin Film Technology

CVD (Chemical Vapor Deposition) is a process for thin film growth through chemical reactions on the substrate surface under vacuum conditions. Its short process duration and the high density of the resulting films have led to the increasing use of CVD in the preparation of inorganic barrier layers in thin film encapsulation processes.

✅ PECVD Thin Film Technology

Plasma Enhanced Chemical Vapor Deposition (PECVD) utilizes plasma to overcome the low reaction activity caused by reaction precursors or process temperatures. This method removes the temperature constraints of the vapor-phase growth process and enables high-quality thin film growth at low processing temperatures.

✅ Atomic Layer Deposition Technology

Similar to CVD, Atomic Layer Deposition (ALD) is a thin film fabrication technique based on surface chemical reactions on the substrate. In addition to similar growth conditions, some precursor materials are interchangeable between the two methods.

The key difference is that CVD maintains two precursors in coexistence within the vacuum reaction chamber, where they undergo chemical adsorption on the substrate surface to form a film. In contrast, ALD enables surface chemical reactions through sequential and separate introduction of each precursor. Each precursor exhibits self-limiting reactivity, and the corresponding self-limiting surface half-reactions deposit material layer by layer on the substrate in the form of a single atomic layer. Continuous self-limiting surface reactions enable atomic layer control and conformal deposition during the film growth process.

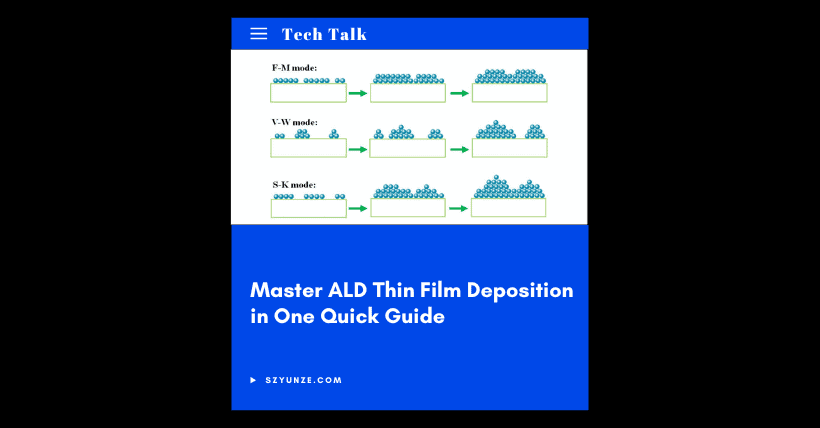

The ALD surface reaction process is continuous and self-limiting, as illustrated in the figure below.

A typical ALD process uses a binary reaction sequence to grow thin films. The two precursors sequentially complete their respective half-reactions on the substrate surface to deposit a monolayer of a binary compound. The active sites on the substrate surface are the basis for ALD film growth. Therefore, before film growth begins, the substrate is often pre-treated to introduce or increase the density of active sites.

For example, using O₂ plasma or UV radiation can significantly enhance the number of hydroxyl (-OH) groups on the substrate surface, as shown in figure (a).

The binary reaction sequence in the ALD process involves four steps, as shown in figure (b):

First, precursor A is introduced into the reaction chamber and undergoes a self-limiting surface reaction with the active sites on the substrate surface, adsorbing a single atomic layer and generating by-products. Subsequently, inert gas Ar is used to purge the chamber and pipeline, removing any residual precursor A and by-products.

Next, precursor B is introduced into the reaction chamber and reacts with the active sites provided by precursor A in another self-limiting surface reaction, adsorbing another atomic layer and generating additional by-products. Finally, Ar again acts as a purge gas to remove residual precursor B and its by-products, re-exposing active sites that can again react with precursor A. At this point, one cycle is complete and a single layer of product has grown. The above cycle is repeated N times, and ALD process parameters are customized according to the required application. Because the number of active sites on the substrate surface is limited, the amount of surface material deposited by each half-reaction is also limited, with each half-reaction reaching a saturation state. If both half-reactions are independently self-limiting, they can proceed sequentially and alternately to enable atomic-scale layer-by-layer deposition.

The ALD process is governed by surface chemical reactions. Since these reactions are carried out alternately and sequentially, the two precursors do not contact each other in the gas phase, preventing gas-phase reactions like those in CVD and avoiding particulate formation on the film surface. Although the precursors are self-limiting, due to different gas flow rates and timing, reactions on active sites occur in sequence. Precursors may physically adsorb via van der Waals forces on already reacted areas and later desorb to continue reacting with other unreacted regions, resulting in conformal deposition. As ALD avoids the randomness of precursor flux, and self-limiting surface reactions result in non-statistical deposition, each surface half-reaction is driven to occur and reach near saturation. Thus, ALD-grown films are extremely smooth and conform closely to the original substrate.

Because almost no active sites remain after film growth, the resulting films tend to be continuous and pinhole-free. This property is critical for producing excellent dielectric films and water vapor barrier layers.

II. Applications of ALD Thin Film Technology

Currently, ALD has great potential in the preparation of ultrathin and high-precision thin films. Typical materials such as Al₂O₃, SiO₂, and ZnO are already used in various electronics industries.

In recent years, thin film deposition and composition control have been widely applied in micro/nano-fabrication technologies, such as in mechanical structures, electrical isolation, and interconnects.

The International Technology Roadmap for Semiconductors (ITRS) includes ALD in the preparation of high-k gate oxides in MOSFET structures and copper diffusion barrier layers in back-end interconnects. Due to the miniaturization of semiconductor processes and the resulting high aspect ratio structures, precise control and conformal coating in film deposition has become a key technical requirement, and the ALD process offers an effective solution.

Moreover, because ALD-grown films are highly dense, they can form excellent gas molecule barriers even at thicknesses below 100 nm. The ultrathin nature of these films supports applications in flexible products. ALD is therefore widely considered one of the most promising protection methods for future optoelectronic devices. Compared with existing encapsulation methods, ALD-based film encapsulation technology offers lighter weight and better flexibility.

Professor S. F. Bent from Stanford University believes ALD, with its atomic-scale precision in film growth, will become an effective solution to thin film encapsulation challenges. Currently, inorganic materials such as Al₂O₃, ZrO₂, SiO₂, and HfO₂ prepared by ALD have been extensively studied and have shown excellent encapsulation results.

However, ALD-based encapsulation films are typically oxides, with stable binary bonds between metals and oxygen atoms in their molecular structure. This results in oxide films having a high Young’s modulus, and as film density and thickness increase, the films tend to become rigid.

Additionally, to meet low-temperature deposition requirements, Plasma Enhanced Atomic Layer Deposition (PEALD) is often used to compensate for low reaction activity at reduced temperatures. However, the introduction of O₂ plasma induces significant residual stress within the film. Due to the inherent properties of ALD-grown inorganic materials—such as low ductility, low fracture toughness, and high brittleness—the mechanical durability and reliability of inorganic encapsulation materials are limited during mechanical movement. Although inorganic films offer excellent encapsulation performance, they cannot maintain stability under strict mechanical motion.

Similar to ALD, Molecular Layer Deposition (MLD) technology can also deposit single molecular layers onto substrate surfaces, and is often used for the growth of organic or hybrid organic-inorganic materials. Notably, MLD often introduces organic components, resulting in films with excellent mechanical properties. However, MLD typically uses organic precursors as surface growth units for single molecular layers. Due to their long-chain organic structures, these precursors have relatively large molecular sizes, which can cause steric hindrance on the substrate surface during half-reactions and block some active sites. This limits the saturation level of surface reactions. The remaining active sites can introduce more defect states inside the film, which can serve as penetration paths for environmental water vapor, significantly affecting the film’s water vapor barrier performance.

III. Fabrication Process of Monolayer and Multilayer Encapsulation Films

During both PEALD and MLD processes, the chamber pressure is maintained at 0.25 Torr, and high-purity Ar (99.999%) with a flow rate of 100 sccm is used as the carrier gas and purge gas for the precursors. The PEALD and MLD processes are conducted in the equipment shown in the figure below.

The growth process of PEALD-Al₂O₃ is as follows: Trimethylaluminum (TMA, 99.9999%) and O₂ plasma are used as the metal precursor and oxidant, respectively, for PEALD-Al₂O₃.

Throughout the process, TMA is kept at room temperature. O₂ plasma is generated using 15 sccm of O₂ (99.999%) under 100 W RF power. The substrate temperature is set to 80 °C. Typical process parameters for PEALD-Al₂O₃ growth are: O₂ plasma pulse for 10 s, purge for 100 s, TMA pulse for 0.04 s, and purge for 100 s.

The growth process of MLD-alucone is as follows: TMA and ethylene glycol (EG, 99.8%) serve as the metal precursor and organic reactant, respectively, for MLD-alucone. Throughout the process, TMA is maintained at room temperature, and EG is heated to 80 °C to enhance reactivity. The substrate temperature is set to 80 °C. Typical process parameters for MLD-alucone growth are: TMA pulse for 0.04 s, purge for 100 s, EG pulse for 4 s, and purge for 120 s.

That concludes the introduction to atomic layer deposition thin film technology. Follow SZYUNZE for more insights into semiconductor technology!

Related:

- NAND Controller Prices Rise on BT Substrate Shortage

- Why ESC Surface Treatment Drives Real Performance?

Disclaimer:

- This channel does not make any representations or warranties regarding the availability, accuracy, timeliness, effectiveness, or completeness of any information posted. It hereby disclaims any liability or consequences arising from the use of the information.

- This channel is non-commercial and non-profit. The re-posted content does not signify endorsement of its views or responsibility for its authenticity. It does not intend to constitute any other guidance. This channel is not liable for any inaccuracies or errors in the re-posted or published information, directly or indirectly.

- Some data, materials, text, images, etc., used in this channel are sourced from the internet, and all reposts are duly credited to their sources. If you discover any work that infringes on your intellectual property rights or personal legal interests, please contact us, and we will promptly modify or remove it.