01

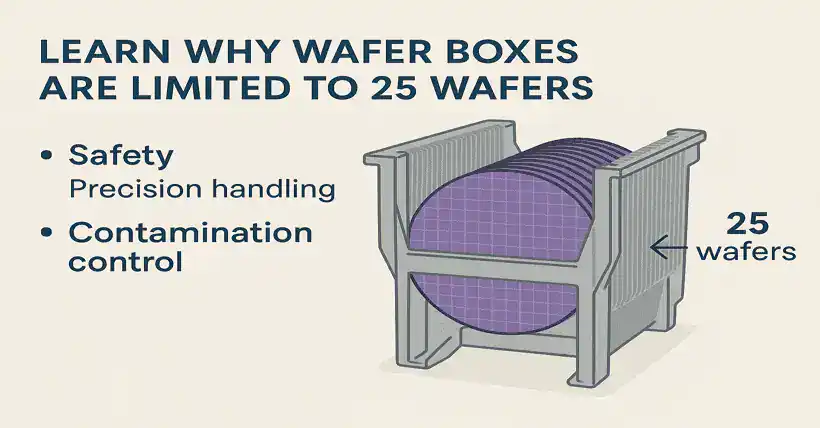

Why Does a Wafer Box Typically Contain 25 Wafers?

Manufacturers explain that extensive experimental studies on process parameters have shown that when a FOUP (Front Opening Unified Pod) holds 25 wafers, work efficiency reaches its highest level. Therefore, the semiconductor industry standard SEMI E1.9 – “Mechanical Specification for 300 mm Wafer Transport and Storage Boxes” – includes corresponding regulations.

Currently, some 12-inch fabs (such as Samsung) place only 24 product wafers in one FOUP. The main reason for adopting batches of 24 wafers is that ASML lithography machines are equipped with two stages. To achieve optimal overlay accuracy, the system requires odd-numbered wafers to be exposed on stage 1 and even-numbered wafers on stage 2.

If batches of 25 wafers were used, the 25th wafer of the previous lot and the 1st wafer of the next lot would both be odd-numbered, causing the lithography machine to waste a switching time between stages.

02

So, Why Was 25 Wafers Finally Chosen?

Loading 25 wafers per wafer box is mainly based on the following reasons:

Optimizing production efficiency and equipment utilization

This design balances production, processing, handling, and economic requirements, making the 12-inch wafer manufacturing process both efficient and reliable. Details are as follows:

Wafer size and load capacity

Wafer size: A 12-inch wafer has a diameter of approximately 300 mm.

Wafer thickness: About 0.775 mm.

FOUP design standards

FOUP must balance size and weight to facilitate handling and transportation.

Process and efficiency considerations

Standardization: The 12-inch wafer manufacturing process has been widely standardized. Processing 25 wafers per batch helps optimize production efficiency and equipment utilization.

Automated handling: FOUPs designed to hold 25 wafers allow automated equipment to efficiently handle batches, thereby improving production throughput.

Convenience of loading and handling: The weight of 25 wafers is within a reasonable range, making it easier for robots or workers to handle without exceeding equipment load limits.

Economy and reliability

Equipment compatibility: Most manufacturing equipment (such as steppers, etchers, etc.) is designed to process batches of 25 wafers, maximizing equipment performance and improving productivity.

Stability and safety: A FOUP loaded with 25 wafers offers good stability during handling, reducing the risk of wafer damage.

Historical reasons and industry practices

Industry convention: Historically, the wafer manufacturing industry has transitioned from smaller wafers (e.g., 6-inch, 8-inch) to 12-inch wafers. During this process, 25-wafer batches became the industry standard to maintain continuity and predictability across different wafer sizes.

Technical standards: SEMI (Semiconductor Equipment and Materials International) has established standards regulating FOUP design and usage. The 25-wafer configuration complies with these standards and is widely adopted globally.

Related:

- Understanding Chamfering in Semiconductor Processes

- How to Fix Wafer Ripple Defects After Surface Cleaning?

- Best Way to Clean Silicon Wafers for Top Performance

- Wafer Cleaning Expiry Time: What You Must Know

- Wafer Wet Cleaning: Required Nitrogen Purity Levels

- How Megasonic Waves Are Made in Wafer Cleaners?

- Metal ECP: How Much Edge Cleaning is Needed?

- How Concentration Polarization Affects Wafer Quality?

Disclaimer:

- This channel does not make any representations or warranties regarding the availability, accuracy, timeliness, effectiveness, or completeness of any information posted. It hereby disclaims any liability or consequences arising from the use of the information.

- This channel is non-commercial and non-profit. The re-posted content does not signify endorsement of its views or responsibility for its authenticity. It does not intend to constitute any other guidance. This channel is not liable for any inaccuracies or errors in the re-posted or published information, directly or indirectly.

- Some data, materials, text, images, etc., used in this channel are sourced from the internet, and all reposts are duly credited to their sources. If you discover any work that infringes on your intellectual property rights or personal legal interests, please contact us, and we will promptly modify or remove it.