Dry etching and wet etching are important steps in pattern transfer during semiconductor manufacturing, each with different mechanisms, advantages, disadvantages, and applicable scenarios.

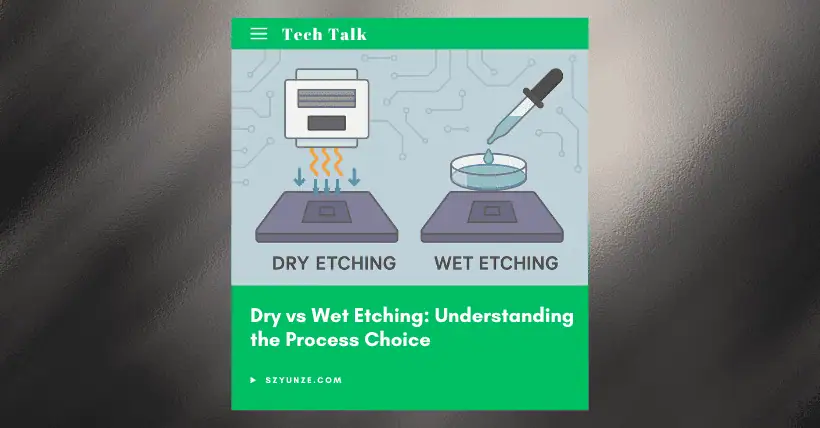

Dry etching uses gaseous plasma or reactive gases to perform anisotropic etching of materials. Its principle mainly involves removing material through plasma, ion bombardment, or chemical reactions. It includes techniques such as Reactive Ion Etching (RIE), Deep Reactive Ion Etching (DRIE), and Ion Beam Etching (IBE).

Wet etching uses liquid chemical reagents, commonly acids or alkalis, to etch materials. Its principle mainly relies on chemical solutions reacting with materials to dissolve them into the liquid phase. It is mostly isotropic etching.

Different gases or solutions are required for etching different materials.

| Material | Dry Etching | Wet Etching |

|---|---|---|

| Si (Silicon) | RIE, DRIE – commonly used for deep silicon etching | KOH, TMAH – used for orientation-selective etching |

| SiO₂ (Silicon Dioxide) | CHF₃, CF₄ and other gases | HF (Hydrofluoric acid) |

| Si₃N₄ (Silicon Nitride) | CF₄, SF₆ and other gases | Hot phosphoric acid |

| Metals | Cl₂, BCl₃, Ar – ion etching | HNO₃/HCl, H₂O₂ mixtures and similar |

| Photoresist | O₂ and other plasma ashing | Wet etching is generally not used for photoresist removal |

There are differences in the application scenarios of dry etching and wet etching.

| Aspect | Dry Etching | Wet Etching |

|---|---|---|

| Advantages | – Directional (anisotropic) etching – Nanometer-scale pattern precision – Strong process repeatability – Easy integration with automation and vacuum processes | – Low cost – Simple process – Good selectivity – Smooth surface |

| Disadvantages | – Expensive equipment – Risk of contamination residue – Slower than wet etching – May cause electrostatic damage | – Isotropic (non-directional), easy undercut – Difficult for high aspect ratio structures – Chemical handling requires attention to safety and environment |

Disclaimer:

- This channel does not make any representations or warranties regarding the availability, accuracy, timeliness, effectiveness, or completeness of any information posted. It hereby disclaims any liability or consequences arising from the use of the information.

- This channel is non-commercial and non-profit. The re-posted content does not signify endorsement of its views or responsibility for its authenticity. It does not intend to constitute any other guidance. This channel is not liable for any inaccuracies or errors in the re-posted or published information, directly or indirectly.

- Some data, materials, text, images, etc., used in this channel are sourced from the internet, and all reposts are duly credited to their sources. If you discover any work that infringes on your intellectual property rights or personal legal interests, please contact us, and we will promptly modify or remove it.