When we started the new design, because most of the time was spent on circuit design and component selection, there was often insufficient experience and consideration during the PCB layout phase.

If there is not enough time and effort provided for the design in the PCB layout phase, it may lead to problems in the manufacturing phase when the design is transformed from the digital domain into physical reality or may result in functional defects.

So, what is the key to designing a circuit board that is truly reliable in both paper and physical form? Let’s explore the following six PCB design guidelines when designing a manufacturable and reliable PCB.

01

Fine-Tune Your Component Placement

The component placement phase in the PCB layout process is both a science and an art, requiring strategic consideration of the key components available on the circuit board. Although this process may be challenging, the way you position electronic components will determine the ease of manufacturing your circuit board and how well it meets your original design requirements.

While there is a conventional general order for component placement, such as sequentially placing connectors, mounting devices for printed circuit boards, power circuits, precision circuits, critical circuits, and so on, there are also some specific guidelines to keep in mind, including:

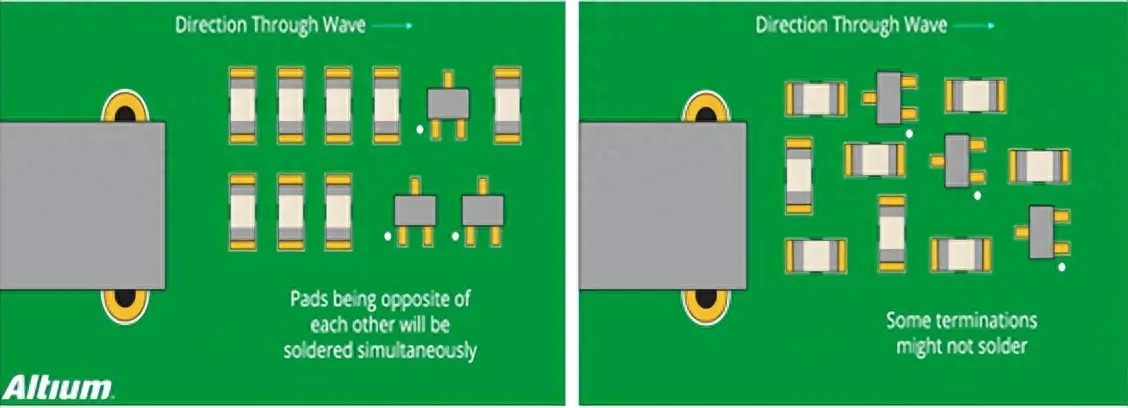

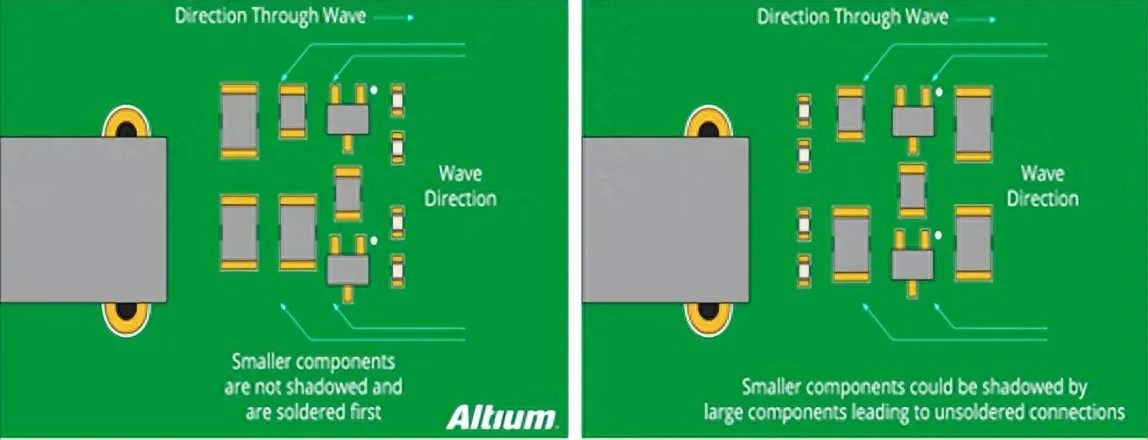

Orientation – Ensure that similar components are oriented in the same direction. This will help achieve an efficient and error-free soldering process.

Arrangement – Avoid placing smaller components behind larger ones, as this may lead to assembly problems for the smaller components due to the influence of soldering on larger components.

Organization – It is recommended to place all surface-mount (SMT) components on one side of the circuit board and all through-hole (TH) components on the top side of the circuit board to minimize assembly steps.

Another important PCB design guideline to keep in mind is that when using a combination of through-hole and surface-mount components, manufacturers may require additional processes to assemble the circuit board, which will increase your overall costs.

02

Appropriately Place power, Ground, and Signal Traces

After placing components, you can proceed to place power, ground, and signal traces to ensure your signals have clean, fault-free pathways. At this stage of the layout process, please keep in mind the following guidelines:

① Positioning the Power and Ground Plane Layers

It is always recommended to place the power and ground plane layers within the circuit board while maintaining symmetry and centering. This helps prevent your circuit board from bending, which is also related to whether your components are correctly positioned.

For supplying power to ICs, it is advisable to use a common channel for each power route, ensuring robust and stable trace widths and avoiding daisy-chained power connections between components.

② Routing Signal Lines

Next, connect the signal lines according to the design in the schematic. It is advisable to follow the shortest and most direct paths between components.

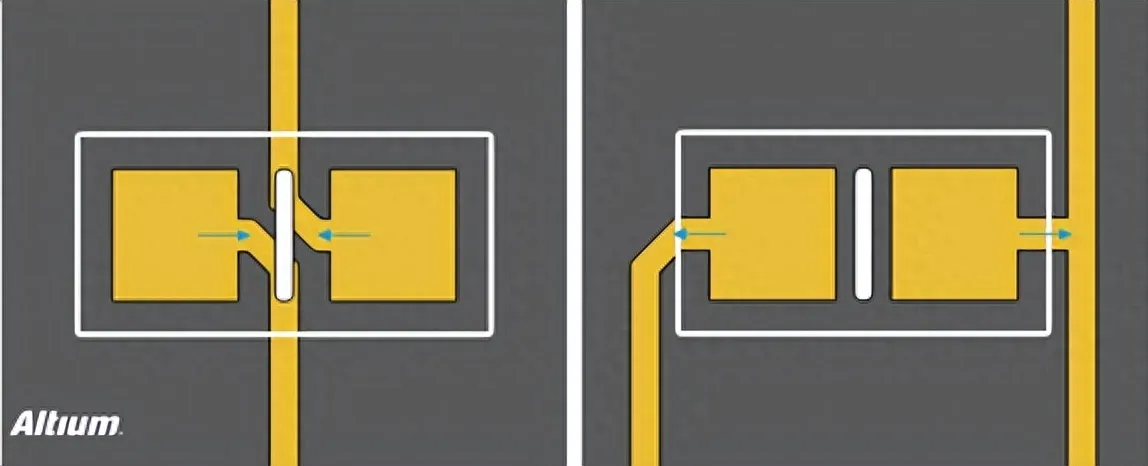

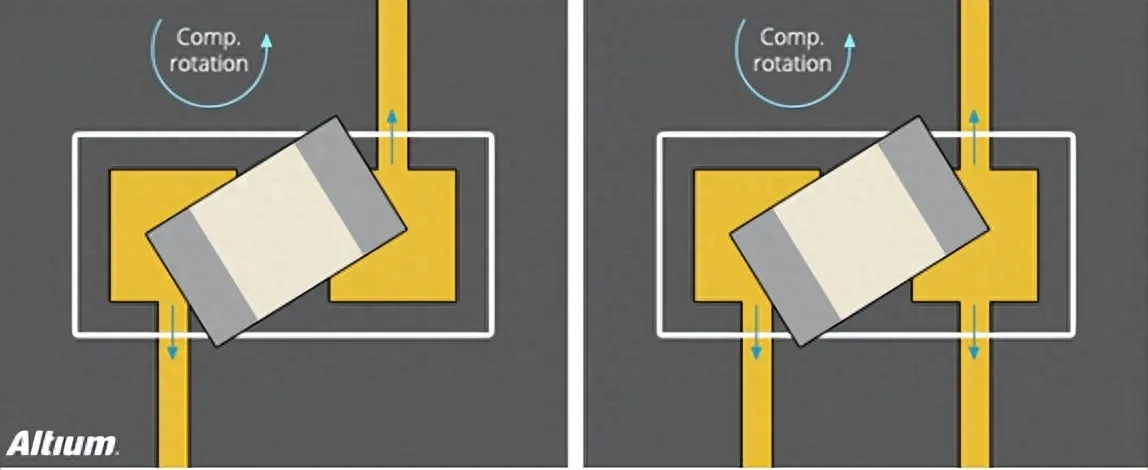

If your components need to be fixed perfectly horizontally without any deviation, it is recommended to route the traces mostly horizontally at the component’s lead-out points on the circuit board, and then switch to vertical routing after the lead-out point.

This ensures that as solder material flows during soldering, the components will remain fixed horizontally, as shown in the upper part of the diagram. The signal routing method in the lower part of the diagram, where solder material flow could potentially cause component deviation during soldering.

③ Defining Trace Width

Your design may require different traces to carry various currents, which will determine the required trace width. Considering this basic requirement, it is recommended to provide a width of 0.010” (10 mil) for low-current analog and digital signals. When your circuit’s current exceeds 0.3 amperes, it should be widened. Here is a free trace width calculator to simplify this conversion process.

03

Effective Isolation

You may have experienced how high-voltage and current spikes in power circuits can interfere with your low-voltage control circuits. To minimize such interference issues, follow the guidelines below:

- Isolation – Ensure that each power route remains separate from the control ground. If you must connect them on the PCB, make sure it is as close to the end of the power path as possible.

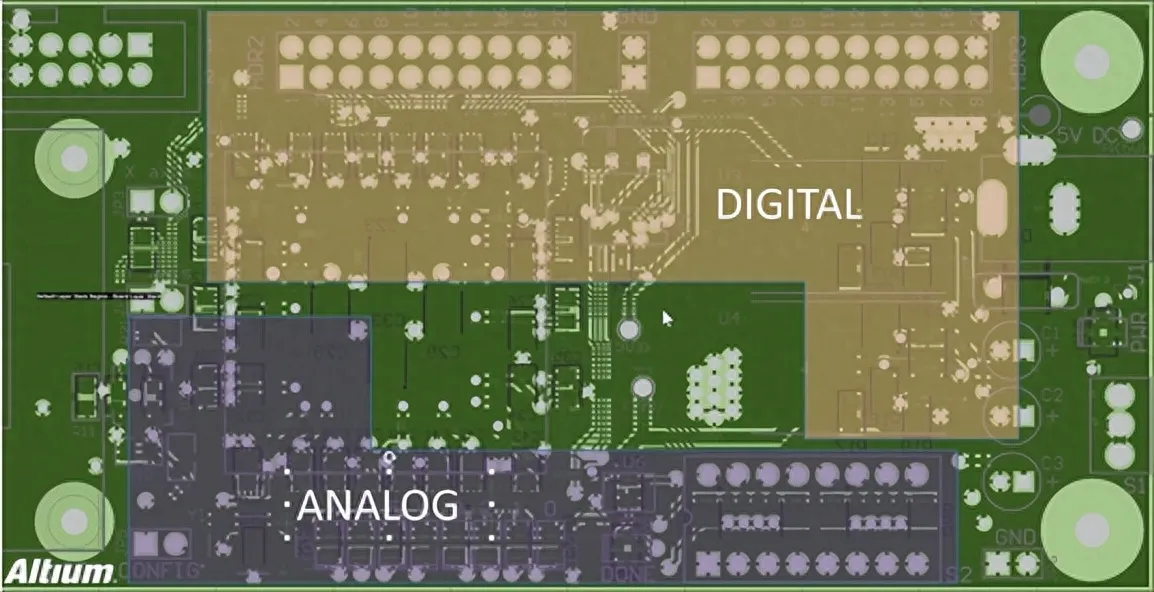

- Arrangement – If you have placed a ground plane on an inner layer, make sure to provide a low-impedance path to reduce the risk of interference from any power circuit and help protect your control signals. You can follow the same guidelines to keep your digital and analog signals separated.

- Coupling – To reduce capacitive coupling due to placing a large ground plane and routing traces above and below it, try to cross analog signal lines only with analog ground.

04

Addressing Heat Issues

Have you ever experienced a drop in circuit performance or even circuit board damage due to heat issues? Many designers have faced problems because they didn’t consider thermal management. Here are some guidelines to keep in mind to help address heat-related issues:

① Identify Troublesome Components

The first step is to begin considering which components will dissipate the most heat on the circuit board. This can be achieved by first finding the ‘thermal resistance’ rating in the component’s datasheet and then transferring the generated heat as per recommended guidelines. Of course, you can add heat sinks and cooling fans to keep component temperatures down and also remember to keep critical components away from any high-heat sources.

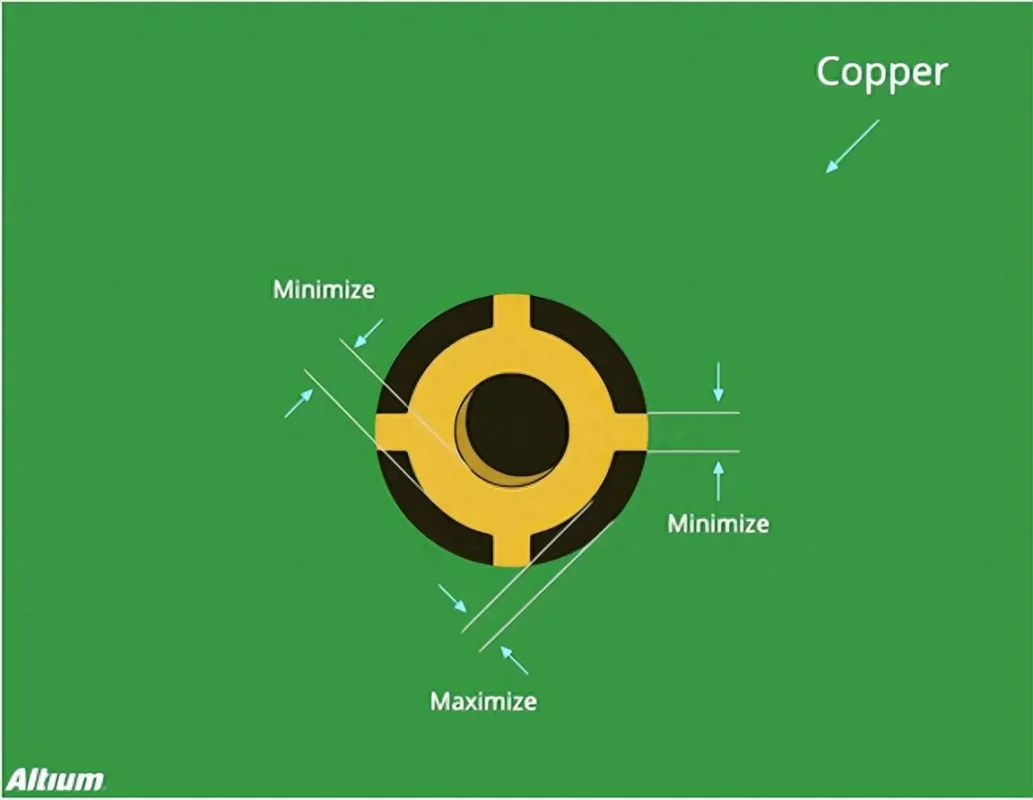

② Add Solder Thermal Pads

Adding solder thermal pads is highly beneficial for producing manufacturable circuit boards, especially for high-copper content components and wave soldering applications on multi-layer circuit boards. Since it can be challenging to maintain the process temperature, it is always recommended to use solder thermal pads on through-hole components to simplify the soldering process by slowing down the heat dissipation at the component pins.

As a general guideline, always use solder thermal pad connections for any through-holes or vias connected to ground planes or power planes. In addition to solder thermal pads, you can add teardrops at the pad-to-trace junctions to provide additional copper/metal support. This will help reduce mechanical stress and thermal stress.

05

Solder Thermal Pad Insights

Many engineers responsible for processes or SMT (Surface Mount Technology) in factories often encounter soldering issues such as solder empties, de-wetting, or cold solder, regardless of how they adjust process conditions or reflow oven temperatures. What’s causing these issues?

Apart from the oxidation of components and PCBs, a significant portion of soldering defects is attributed to a layout design flaw on the circuit board. The most common problem is connecting certain pins of components to large copper areas, which results in poor soldering for these component pins after reflow soldering. Some hand-soldered components may also experience problems like cold solder or bridging due to similar circumstances, and in some cases, components may be damaged due to prolonged heating.

In PCB design, it is often necessary to lay large copper foils for power (Vcc, Vdd, or Vss) and ground (GND) purposes. These large copper foils are typically directly connected to the pins of control circuits (ICs) and electronic components.

Unfortunately, heating these large copper foils to the solder melting temperature usually takes more time compared to individual solder pads (meaning slower heating), and they dissipate heat faster. When one end of such large copper foils is connected to small components like resistors or capacitors, while the other end is not, soldering issues can occur due to inconsistent solder melting and solidification times.

If the reflow soldering temperature curve is not adjusted properly and the preheating time is insufficient, the component pins connected to the large copper foils may not reach the solder melting temperature, resulting in poor solder joints.

During manual soldering, component pins connected to large copper foils may not complete soldering within the specified time due to rapid heat dissipation.

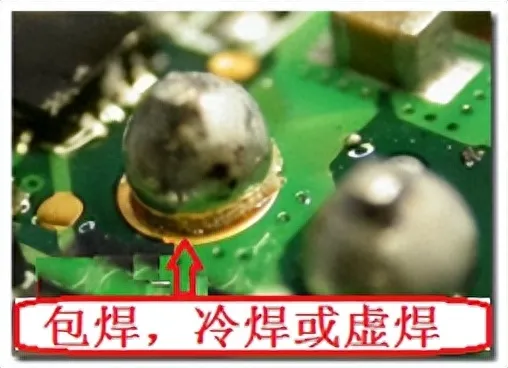

The most common soldering defects are observed as bridging and cold solder, where the solder only adheres to the component’s pins and doesn’t connect to the PCB pad. Visually, the solder joint appears as a spherical shape. Furthermore, operators may unknowingly increase the soldering iron’s temperature or overheat the components to get the pins soldered to the PCB, potentially causing component damage. As shown in the diagram below.

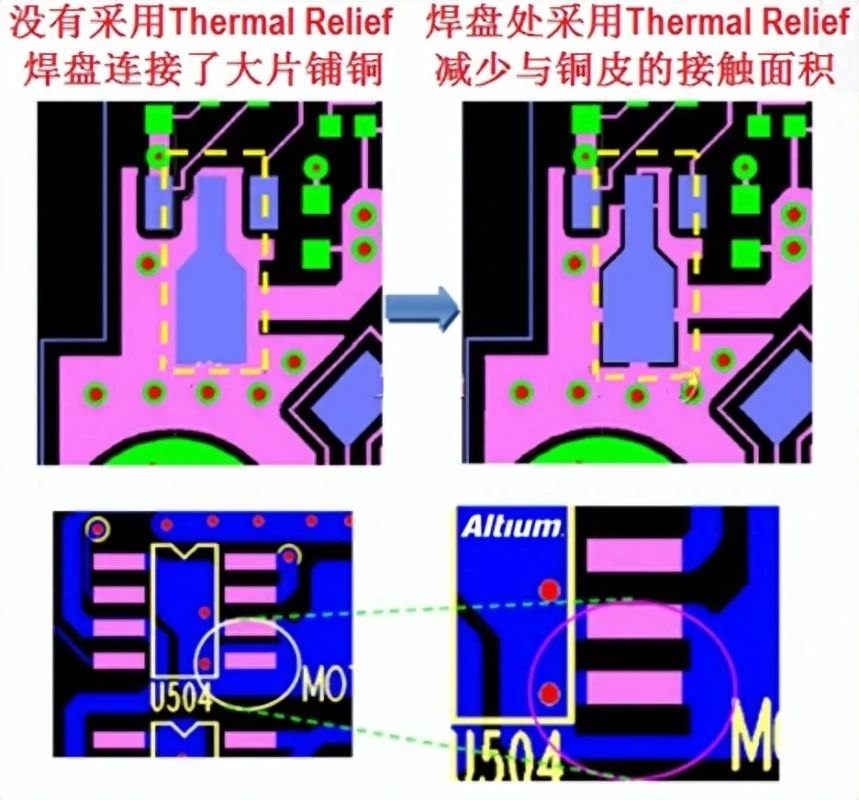

Now that we know the problem points, there is a solution commonly used, known as Thermal Relief Pads, to address soldering issues caused by connecting component pins to large copper areas.

As shown in the diagram below, on the left, the layout does not use thermal relief pads, while on the right, the layout already employs thermal relief pad connections. You can observe that the contact area between the pad and the large copper area is reduced to just a few thin traces. This significantly limits the loss of temperature on the pad, leading to improved soldering results.

06

Review Your Work

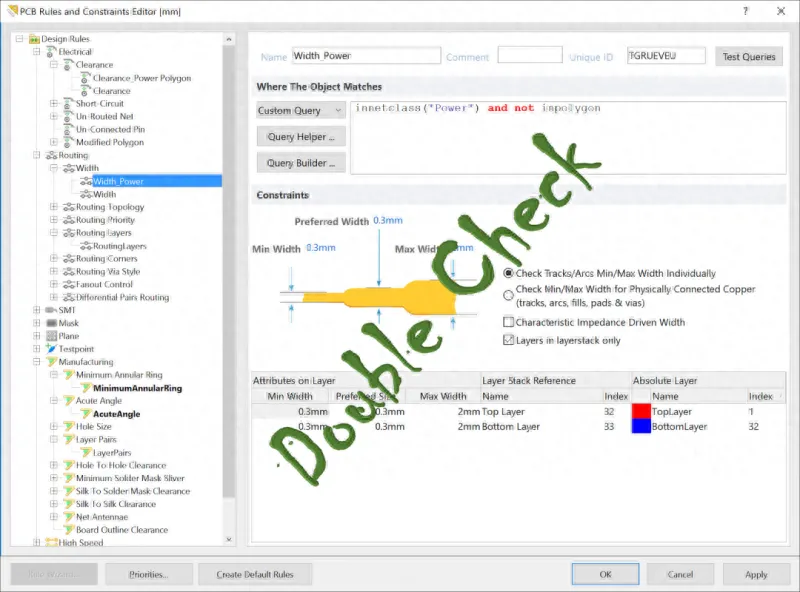

When you’re tirelessly putting all the pieces together for manufacturing, it’s easy to discover problems only at the end of a design project, which can be overwhelming. Therefore, at this stage, a double and triple check of your design work can mean the difference between success and failure in manufacturing.

To assist in the quality control process, we always recommend starting with Electrical Rule Checks (ERC) and Design Rule Checks (DRC) to verify that your design fully complies with all rules and constraints. With these two systems, you can easily perform checks on aspects like gap width, trace width, common manufacturing settings, high-speed requirements, and shorts, among others.

When your ERC and DRC yield error-free results, it is advisable to review the routing of each signal, carefully confirming that you haven’t missed any information, one signal at a time, from the schematic to the PCB. Additionally, utilize your design tool’s probing and shielding features to ensure that your PCB layout matches your schematic.

07

Words in the End

When you have grasped these design guidelines that every PCB designer needs to know, by following these recommendations, you will soon be able to design powerful and manufacturable circuit boards with ease, possessing truly high-quality printed circuit boards.

Good PCB design practices are essential for success, and these design rules lay the foundation for building and solidifying a practice of continuous improvement in all design endeavors.

Related:

- Find Out Essential Simulations for Chip Packaging Process

- Emergence of Southeast Asia as a Hub for PCB Manufacturers

- Debunking Gray Dust Balance: Computer Cleaning Myths

- Easy DIY: Add Type-C Port to Regular Charger!

- How to do PCBA Testings and what essential equipments

- iFixit Steam Deck Repair Kit: SSD and Fan Upgrades

Disclaimer: This article is created by the original author. The content of the article represents their personal opinions. Our reposting is for sharing and discussion purposes only and does not imply our endorsement or agreement. If you have any objections, please contact us through the provided channels.